Tips for Maintaining Small Engines for Longevity

When it comes to small engines, I’ve learned that the secret to getting the most out of them isn’t just about fixing them when they break down. It’s about keeping them in top shape throughout their lifespan, ensuring they run smoothly for years to come. Having worked with all kinds of small engines over the years—from lawnmowers to snow blowers, and even small power generators—I’ve picked up a few tried-and-true tips that make a huge difference when it comes to engine longevity. Proper care and maintenance can save you a lot of time, money, and frustration in the long run, and in this article, I’ll share some of the most valuable lessons I’ve learned along the way.

Small engines, like any other mechanical system, need regular attention to keep running at peak performance. But it’s not just about checking the oil every few months or filling the gas tank—there are other, more nuanced aspects that can significantly impact how long your engine lasts. Whether you’re a DIY enthusiast or just looking to extend the life of your equipment, these maintenance tips will help ensure your small engine is always ready when you need it.

Evolution Racing Engines

45 Elm Pl A, Amityville, NY 11701, USA

1. Regularly Change the Engine Oil

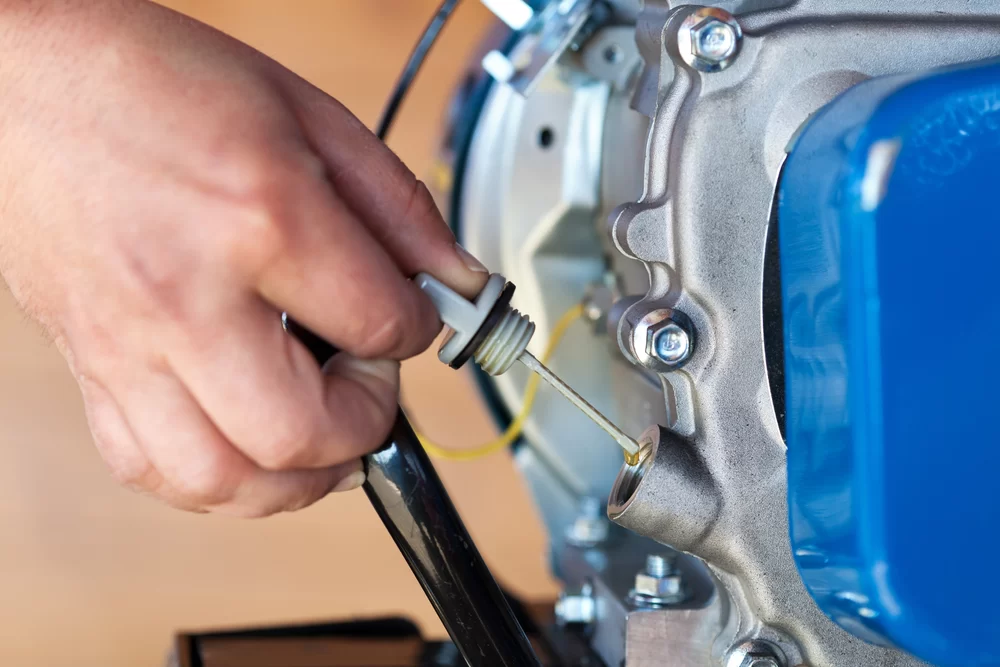

One of the most important and easiest ways to extend the life of any small engine is to change the oil regularly. I’ve always been meticulous about changing the oil on my engines, and it’s made a world of difference in how long they last. Fresh oil helps to lubricate the internal components of the engine, reducing friction and wear. Over time, engine oil degrades as it accumulates dirt and debris, and this can lead to increased engine temperatures and even catastrophic failure if not addressed.

When it comes to oil changes, I follow the manufacturer’s guidelines, which often suggest changing the oil every 20 to 50 hours of operation, depending on the type of engine. For example, a lawnmower that’s used frequently might need oil changes more often than a snowblower that’s only used seasonally. Don’t forget to check the oil level regularly—if it’s too low, the engine won’t be properly lubricated, which could cause serious damage.

Additionally, when changing oil, I always make sure to use the type and viscosity recommended in the owner’s manual. Using the wrong oil can affect engine performance and longevity. And while I’m on the topic, remember to replace the oil filter if your engine has one. A clean filter ensures that only clean oil circulates through the engine, keeping it in better shape for longer.

Rhino and jah

200 Hinsdale St, Brooklyn, NY 11207, USA

2. Clean the Air Filter Frequently

The air filter plays a crucial role in preventing dirt, dust, and debris from entering the engine. A dirty air filter can reduce airflow, causing the engine to overheat and work harder than it should. This is something I’ve learned the hard way after noticing a dip in engine performance, only to find that the air filter was clogged with grass and dust.

To keep things running smoothly, I check and clean the air filter regularly—usually after every 10 to 20 hours of operation. If the filter is too dirty, I replace it. It’s a simple and cost-effective way to maintain the engine’s efficiency and prevent larger issues down the road. I also make sure to clean the filter with a mild detergent if it’s washable. If it’s a paper filter, I just replace it when it gets too dirty. An air filter in poor condition will make your engine work harder, and that’s never a good thing for longevity.

3. Maintain the Fuel System

Maintaining the fuel system is another essential aspect of keeping a small engine running for years. I’ve encountered countless engine issues that were the result of poor fuel maintenance. Stale or contaminated fuel is one of the biggest culprits behind engine problems. Over time, gasoline can break down, leading to clogged carburetors or fuel lines. I always make sure to use fresh fuel and add a fuel stabilizer when I plan on storing an engine for an extended period—especially over the winter months when I know I won’t be using my equipment.

Also, it’s crucial to drain the fuel from the tank if I’m storing the engine for a long time. Leaving fuel in the system can cause gum and varnish buildup, leading to issues when I try to start it up again. If you forget to drain the fuel, it’s often worth disassembling the carburetor for a cleaning. This process can be a bit involved, but I’ve found that doing it myself is far less expensive than taking it to a mechanic for a full fuel system overhaul.

Additionally, I recommend replacing the fuel filter every couple of years. Fuel filters can become clogged over time, which can restrict the flow of fuel and impact engine performance. It’s a small investment for preventing larger problems.

4. Keep the Spark Plug in Good Condition

The spark plug is another critical component that affects engine performance. I’ve learned that a dirty or worn-out spark plug can lead to starting problems, poor fuel efficiency, or rough idling. To ensure my engines run smoothly, I check the spark plug every season, cleaning it with a wire brush if necessary. If it’s showing signs of wear—like corrosion or a gap that’s too wide—I replace it. It’s a simple task that takes only a few minutes but can make a world of difference in how the engine runs.

In addition to inspecting the spark plug, I also check the spark plug wire for any cracks or damage. A faulty spark plug wire can lead to misfiring or engine failure. Replacing it when necessary helps to maintain smooth operation and prevent future issues.

5. Store Your Engine Properly

One of the biggest mistakes I made early on was neglecting how I stored my small engines during the off-season. Whether it’s a lawnmower, a pressure washer, or a snowblower, improper storage can lead to rust, stale fuel, and other problems that shorten the life of the engine. Now, I make sure to store my engines in a dry, cool location, away from extreme temperatures and moisture.

If I’m storing an engine for an extended period, I take a few extra steps to ensure it’s properly preserved. First, I clean the engine thoroughly, removing any dirt, grass, or debris. Then, I perform an oil change and drain any remaining fuel. For extra protection, I sometimes cover the engine with a tarp to shield it from dust and debris.

For outdoor equipment like lawnmowers or leaf blowers, I also elevate the machines off the ground using blocks or a shelf, so they don’t sit in direct contact with moisture. This has helped to prevent rust on metal parts, particularly around the exhaust and other vulnerable areas.

6. Regularly Inspect the Engine

Last but not least, regular inspections have become an essential part of my maintenance routine. It’s easy to overlook minor issues when everything seems to be running smoothly, but I’ve learned that catching small problems early can save a lot of headaches later on. Each season, I go over the engine with a fine-tooth comb, checking for loose bolts, frayed wires, or any signs of wear that could lead to bigger problems.

I also keep an eye on the engine’s performance. If I notice any unusual vibrations, odd noises, or irregularities in how it runs, I’ll investigate further. These can be early warning signs of a larger issue that needs attention before it turns into an expensive repair.

Whether you’re a casual user or a dedicated enthusiast like me, investing the time to inspect your equipment regularly can make a world of difference in the long run. It’s better to catch a problem early than to let it evolve into something that requires costly repairs.

Maintaining small engines doesn’t have to be overwhelming. With the right care and attention, I’ve found that my engines run smoother, last longer, and perform better than I ever expected. And for those times when I need professional help or just don’t have the time to handle things myself, I always know I can count on trusted services like Rescue & Towing for assistance with everything from towing to engine repairs.