C&W Machine Shop

Auto Repair StationsSouth CarolinaAnderson CountyAndersonFlat Rock Road

Anderson County . South Carolina

Close Now

- Overview

- Intro

- Photos

- Location

- Reviews

- +1 864-401-8044

- 1101 Flat Rock Rd, Anderson, SC 29624, USA

Operating Hours

C&W Machine Shop Introduce

Within the diverse and critical "Auto Repair Stations" platform category, **C&W Machine Shop** occupies a highly specialized and indispensable position. Unlike conventional auto repair garages that focus on vehicle assembly and component replacement, C&W Machine Shop delves into the intricate world of precision machining, fundamental to engine rebuilding, custom part fabrication, and specialized repairs for both automotive and industrial applications. Based on its designation as a "Machine Shop," this introduction will objectively outline the highly technical environment, the precise services and goods offered, the distinguishing features that set them apart as masters of metallurgy and mechanics, and the promotional strategies commonly employed by such a unique and crucial service provider.

The **environment** at C&W Machine Shop is fundamentally different from a general automotive service center. It’s a space dominated by heavy machinery, precision tools, and an atmosphere of focused, meticulous work. While there might be a small, functional reception area, the core of the operation lies within the workshop itself, which is meticulously organized to accommodate various machining processes. You would expect to see:

- **Lathes:** For turning and shaping cylindrical parts.

- **Milling Machines:** For creating custom shapes, slots, and flat surfaces with high accuracy.

- **Grinders:** Including surface grinders, cylindrical grinders, and specialized crankshaft grinders, vital for achieving exact tolerances and smooth finishes.

- **Boring and Honing Machines:** Specifically for engine blocks and cylinders, ensuring precise diameters and surface finishes for optimal piston ring seal.

- **Specialized Welding Equipment:** For intricate repair welds on cast iron, aluminum, and other metals.

- **Metrology Tools:** A range of precision measuring instruments like micrometers, calipers, bore gauges, and surface plates, essential for quality control.

The shop would likely be well-lit, clean, and perhaps climate-controlled in certain areas to maintain material stability. The air might carry the distinct scent of cutting fluids and metal, indicative of the ongoing fabrication and repair work. Safety protocols would be strictly adhered to, given the powerful machinery in operation. Technicians, often referred to as machinists or engine builders, would display a high level of technical skill and attention to detail, working with precision that borders on artistry. The overall impression is one of a highly capable engineering facility where raw materials and worn components are transformed into perfectly functioning parts.

The **services and goods for sale** at C&W Machine Shop are highly specialized, focusing on the repair, modification, and creation of metal components. While their expertise often benefits the automotive sector (hence their inclusion in "Auto Repair Stations"), their capabilities frequently extend to industrial, agricultural, and heavy equipment applications. Their offerings commonly include:

- **Engine Component Machining:** This is a core service, encompassing:

- **Cylinder Head Services:** Resurfacing, valve seat replacement/repair, valve guide replacement, porting and polishing for performance enhancement, and crack repair.

- **Engine Block Machining:** Cylinder boring, honing, deck surfacing, main bearing line boring/honing, and cam bearing installation.

- **Crankshaft Grinding and Polishing:** Resizing and restoring crankshafts to precise specifications, often for undersize bearings.

- **Connecting Rod Reconditioning:** Resizing and ensuring proper alignment of connecting rods.

- **Flywheel Resurfacing:** To ensure proper clutch engagement.

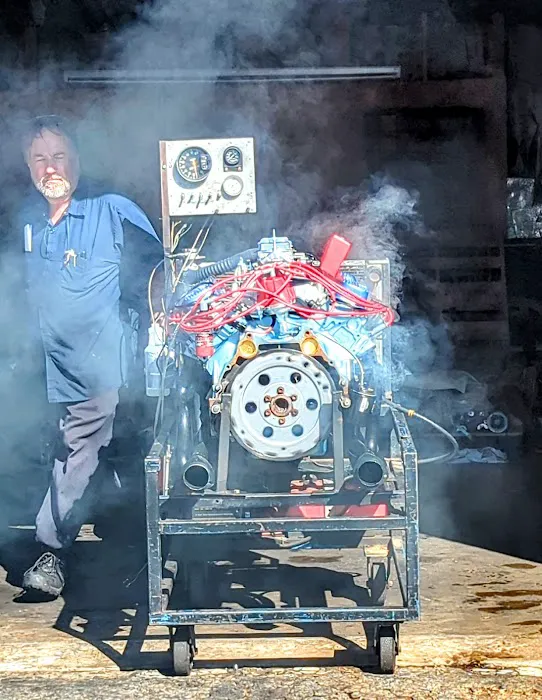

- **Full Engine Rebuilding and Assembly:** Taking individual machined components and assembling complete engines, often for performance, classic car restoration, or heavy-duty applications.

- **Custom Part Fabrication:** Designing and manufacturing bespoke metal parts that are no longer available, require custom dimensions, or are needed for specialized applications. This could include brackets, adapters, or unique shafts.

- **Welding and Metal Repair:** Expert welding services for cast iron, aluminum, stainless steel, and other exotic metals, often used for repairing cracked engine blocks, cylinder heads, or other damaged components.

- **Component Balancing:** Dynamically balancing rotating assemblies (crankshafts, flywheels, pistons, connecting rods) to reduce vibration and improve engine longevity and performance.

- **Driveshaft Repair and Fabrication:** Repairing, balancing, or custom-building driveshafts for various vehicles and equipment.

- **Industrial and Agricultural Equipment Component Repair:** Extending their machining expertise to repair worn or broken parts from heavy machinery, pumps, transmissions, and other industrial components.

- **Hydraulic Cylinder Repair:** Machining and repairing components for hydraulic systems found in heavy equipment.

- **Parts Sales:** While primarily a service provider, they would supply the necessary high-quality engine components (pistons, rings, bearings, valves, gaskets) for their rebuilds and custom projects, often sourcing specialized parts directly.

Several **features** profoundly distinguish C&W Machine Shop within the automotive and broader industrial repair landscape. Firstly, their **unparalleled precision and technical expertise** in machining is their most significant asset. They operate at tolerances far beyond what a general repair shop can achieve, ensuring that rebuilt engines and custom parts perform flawlessly. Their highly skilled machinists are master craftsmen. Secondly, their **problem-solving capabilities** are exceptional. When a part is obsolete, excessively worn, or simply doesn't exist for a custom build, a machine shop can often create or restore it, making them indispensable for classic car restorers, performance builders, and industrial clients facing unique challenges. Thirdly, the **longevity and cost-effectiveness** of their work are key. Instead of simply replacing expensive components, C&W Machine Shop can often repair and restore them to "better than new" specifications, saving clients money in the long run and extending the life of valuable equipment. Lastly, their ability to serve **diverse sectors** (automotive, industrial, marine, agricultural) highlights their versatility and deep understanding of metallurgy and mechanical principles across various applications, making them a go-to specialist for complex component issues.

In terms of **promotional information**, C&W Machine Shop would employ strategies that emphasize their highly specialized skills, precision, and ability to solve complex problems. Common **promotional activities** include:

- **Detailed Online Portfolio:** A robust website showcasing specific examples of their work, such as before-and-after photos of engine blocks, cylinder heads, and custom-fabricated parts, along with explanations of the machining processes involved.

- **Client Testimonials and Case Studies:** Featuring reviews from clients who have benefited from their specialized services, especially those with unique or challenging projects, to build credibility and demonstrate problem-solving capabilities.

- **Targeted Advertising to Niche Markets:** Reaching out to classic car restoration shops, performance engine builders, heavy equipment operators, industrial businesses, and agricultural clients through industry-specific publications, trade shows, and online forums.

- **Educational Content:** Creating blog posts or videos that explain the importance of engine machining, the benefits of rebuilding vs. replacing, or the precision involved in specific machining processes, positioning themselves as authoritative experts.

- **Partnerships with General Auto Repair Shops and Mechanics:** Establishing referral relationships with general garages that do not possess machining capabilities, becoming their go-to specialist for engine and component work.

- **Showcasing Equipment and Capabilities:** Using high-quality photos and videos of their advanced machinery and skilled machinists at work on their website and social media channels to convey their professionalism and technical prowess.

- **Emphasis on Quality Control and Precision:** Promoting their rigorous quality control processes and adherence to tight tolerances, assuring clients of the superior results of their work.

- **Local Business-to-Business (B2B) Outreach:** Direct communication with local businesses in relevant industries to offer their specialized services.

- **Participation in Automotive and Industrial Trade Shows:** Attending local and regional events to network with potential clients and industry professionals.

In conclusion, C&W Machine Shop stands as a critical and highly specialized entity within the "Auto Repair Stations" category, extending its precision engineering capabilities to encompass a wide array of automotive, industrial, and heavy equipment needs. Their unique environment, expert machining services, unwavering commitment to precision, and strategic promotional efforts establish them as an invaluable resource for anyone requiring the restoration, customization, or precise repair of metal components and engines.

C&W Machine Shop Photos

C&W Machine Shop Location

C&W Machine Shop Customer Reviews

Mr. Wayne is a great machinist and a even better person has always looked out for me and my best interest. He does the best work in the upstate and his prices are by far the best in the upstate. Wayne always gives me straight forward answers to any questions that I have. THE BEST MACHINE SHOP IN THE UPSTATE!!!!

Oct 04, 2024 · Ahmad Singleton

When you don't have a business sign out front, but you are covered up in work for weeks speaks loud and clear! They came highly recommended and they delivered great service!

Jul 15, 2024 · Timothy Ward

They communicated with me well over the phone on answering my questions. I'm not an official customer yet only due to them being months behind in getting the work they have on hand out the way first for me to then bring in what I want them to have honors in doing for me.

May 07, 2024 · Adarius Bell

Wayne did amazing job on my dart block. Gave me options and straightforward answers.very fast and didn't break the bank.Using him for all my speed needs.Thanks Wayne

Sep 16, 2023 · akeem ludel

Great service, quick turn around, good prices

Apr 25, 2021 · radisson wright

More Auto Repair Stations Near Me

Bouknight Auto Service

5901 SC-81, Starr, SC 29684, USA

(60)

Close Now

TheGRgarage

1500 Airline Rd, Anderson, SC 29624, USA

(1)

Close Now

The Ram House

1412 Hayes Rd, Anderson, SC 29624, USA

Close Now

Ed Powell's Auto Salvage

3715 Mabry St, Anderson, SC 29624, USA

(133)

Close Now

J's MOBILE DIESEL SERVICE 24 HourTruck Repair

100 Shiflet Rd, Anderson, SC 29624, USA

(62)

Close Now

Minyard's Auto Collision Services

4123 SC-81, Anderson, SC 29624, USA

(50)

Close Now

Cross Air Cooled, LLC

6506 SC-81 S, Starr, SC 29684, USA

(12)

Close Now

Quality Tire Services

4015 S Main St, Anderson, SC 29624, USA

(438)

Close Now

M & P Auto Repair

3507 S Murray Ave, Anderson, SC 29624, USA

(15)

Close Now

Belltec Collision

509 Haynie St, Anderson, SC 29624, USA

(68)

Close Now

All Charged Up

1114 Travis Rd, Anderson, SC 29626, USA

(100)

Close Now

Freeman's Tire

3299 S Main St, Anderson, SC 29624, USA

(336)

Close Now

Recommended

salvage yards riverside ca

(607)

+1 800-962-22773760 Pyrite St, Riverside, CA 92509, USA

clean energy fuel station

8 Grand Blvd, Brentwood, NY 11717, USA

george's fontana

(242)

+1 909-822-34029684 Sierra Ave., Fontana, CA 92335, USA

smog check in san fernando ca

(48)

+1 661-944-290037855 90th St E #B, Littlerock, CA 93543, USA

autozone auto parts aberdeen car parts

(906)

+1 818-485-052113200 Osborne St, Arleta, CA 91331, USA

empire mazda service & parts

(142)

+1 631-479-3874660 E Jericho Turnpike, Huntington Station, NY 11746, USA

Related Categories

Popular

Tips for Maintaining Your Car's Side Skirt Paint Chips

Jul 28, 2025

The Role of Spark Plugs in Your Engine's Performance

Jul 28, 2025

The Benefits of Using a Car Phone Mount

Jul 28, 2025

How to Replace Your Car's Interior Reading Lights

Jul 27, 2025

Common Problems with Car Power Outlets and How to Fix Them

Jul 27, 2025

Understanding Your Car's Canister Vent Solenoid – Symptoms, Function & Repair

Jul 27, 2025

Understanding Your Car's EGR Temperature Sensor: Function, Issues, and Maintenance

Jul 26, 2025